1410 WEST LARK INDUSTRIAL PARK | FENTON, MO 63026 | PH: 636-677-3364 | FAX: 636.305.1265

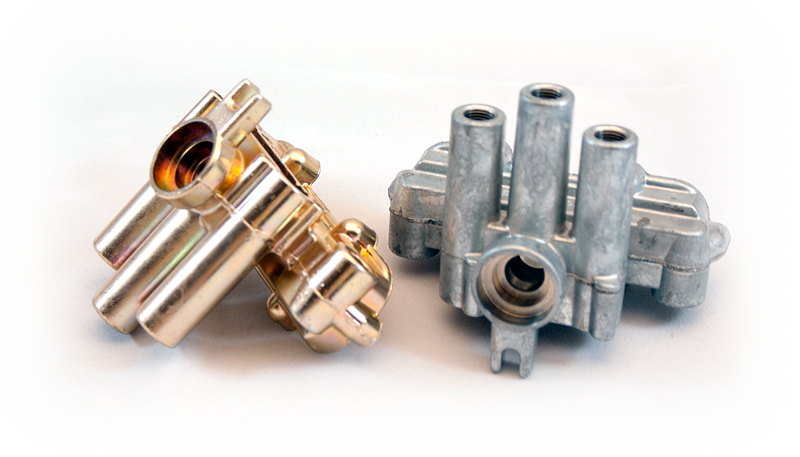

Zinc Die Casting

PRODUCTION CASTINGS HAS BEEN PRODUCING ALUMINUM DIE CASTINGS & ZINC DIE CASTINGS, SINCE 1976.

We can offer many different die casting solutions because of our wide selection of die casting machines.

Zinc die casting alloys offer a broad range of excellent physical and mechanical properties. Thinner sections and walls can be die cast in zinc alloy than in any of the commonly used die casting alloys.

Zinc alloy generally allows for greater variation in section design and can achieve tighter dimensional tolerances.

Zinc is the easiest alloy to cast; it offers high ductility, high impact strength and is easily plated.

Zinc is economical for small parts, has a low melting point and promotes long die life.

Zinc die castings are versatile and can be found in many of the things that we use everyday, such as electric motors, seat belts, computers, hand tools, electrical connectors and faucets.

THE DIE CASTING PROCESS

Die casting is a versatile, efficient and economical process for producing engineered metal parts.

Die casting offers a broader range of shapes and components than any other manufacturing technique.

The die casting process requires a steel mold. These reusable steel molds, called dies, can be designed to produce complex shapes with a high degree of accuracy and repeatability.

The dies are mounted into a machine that injects molten metal into the dies under high pressure. Once the molten metal has solidified, the die is opened and the casting is ejected from the mold. The die is then closed and the process starts over.

Aluminum Cold Chamber Die Casting Machine

ADVANTAGES OF DIE CASTING

The die casting process provides complex shapes within closer tolerances than many other mass production processes. Little or no machining is required and thousands of identical castings can be produced in a very short time.

Die castings have a long service life because they are durable, dimensionally stable, and heat resistant.

Die cast parts are stronger than plastic injection molded parts having the same dimensions. Die castings can be produced with thinner wall sections that are not possible with other casting methods.

Die castings can be smooth or textured and they are easily plated or painted with a minimum of surface preparation.

Die castings offer simplified assembly by providing integral fastening elements such as bosses and studs. Holes can be cored and made to tap drill sizes or external threads can be cast.

Zinc Hot Chamber Die Casting Machine